Backing sand or floor sand is used to back up the facing sand and is used to fill the whole volume of the molding flask. It may be classified generally into three different types.

Molding Sand Constituents Types And Properties Bernier Metals

It is fine soft.

. Core sand is used for making cores and it is sometimes also known as oil sand. The molten metal is poured into the moulds to produce castings. 1 natural moulding sands 2 synthetic or high silica sands and 3 special sands.

When the moisture is removed from green sand it is known as dry sand. The mould produced by. In general there are three types of conventional sand molds that are used in sand casting operations.

21 Backing sand or floor sand. Core sand is highly rich. The natural sand contains enough binder to be used for casting molds.

KINDS OF MOULDING SAND. Types of Moulding Sands. Sands which are used to make mould is called moulding sand.

The following are the primary elements of moulding sands. Different types of Molding Sand. Some common sand types include moulding sand washed sand beach sand mason sand and silica sand.

A good moulding sand contains impurities below 2 per cent. According to the different binders foundry sand used for moulding can be divided into green sand water glass sand and resin sand. It is mixture of silica and 15.

What Type of Sand is Used for Sand Casting. When the moisture is removed from green sand it is known as dry sand. Such type of castings requires the use of cores.

This sand is mostly used to casting both ferrous and nonferrous material. The clay used to make wet clay sand is bentonite clay. Sand casting using green sand is quick and inexpensive since the sand can be reused.

Parting sand consists of fine grained clay free dried silica sand sea sand or burnt sand with some parting compounds. In terms of the synthetic sand it is made by mixing basic sand 85 to 91 silica sand 6 to 11 binder 2 to 8 water or moisture content and other additives and grinding them in a certain proportion in appropriate equipment. The downside is that the sand is a soft mold and.

Basic sand tests can measure tensile strength friability moisture content permeability green compression strength compact ability loss on ignition volatiles content grain size and distribution and many more. There are many different sand options accounting for natural and artificially produced sand each with its own pros and cons. The green sand is the natural sand containing sufficient moisture in it.

Green sand refers to the sand molds formed from wet sand and is sometimes referred to as clay. The mould produced by. Casting of materials without use of moulding sand is impossible.

Backing sand or floor sand is used to back up the facing sand and is used to fill the. When the moisture is removed from green sand it is known as dry sand. In dry sand moulding more water is present when making mould as it is beneficial in promoting dry bond strength after storing.

Green sand is also known as tempered or natural sand which is a just prepared mixture of silica sand with 18 to 30 percent clay having moisture content from 6 to 8. Classification Of Mold Sands. Green sand is an aggregate of sand bentonite clay pulverized coal and water.

This sand has more rigidity thermal stability and strength. The moulding is a process of making a cavity or mould out of sand by means of a pattern. The clay contain of green send is about 30 and water contain is about 8.

Each test obtained very specific characteristics of the sand. Dry-sand mold sand SRCWynndanzur. The largest portion of the aggregate is always sand which is often a uniform mixture of a form of silica.

Green sand moulding is carried with sand of low moisture content 3 to 5. Refractoriness is defined as the ability of molding sand to withstand high temperatures without breaking down or fusing thus facilitating to get sound casting. It is mixture of silica and 15.

Refractoriness can only be increased to a limited extent. It is a highly important characteristic of molding sands. Organic binders are used instead of clay products.

Green sand which is also known as natural sand is the mostly used sand in moulding. Dry sand is made by baking or drying the mold made from the green sand in a decent oven. Moulding sands types.

Dry sand is the type of green sand from which moisture is being removed. The dry sand contains a mixture of 15 to 20 of clay and silica. The sand mold is in an uncured state as the metal is being poured.

June 15 2021. Loam san aniketkumarbokp9mncb aniketkumarbokp9mncb 20092018 Science Secondary School answered Explain different type of molding sand 2. The green sand is the natural sand containing sufficient moisture in it.

Clay and water used to increase binding strength of sand. According to their types of moulding sands use in the foundry moulding sands are classified into following categories. Almost every manufacturing industries uses moulding sand to make moulds.

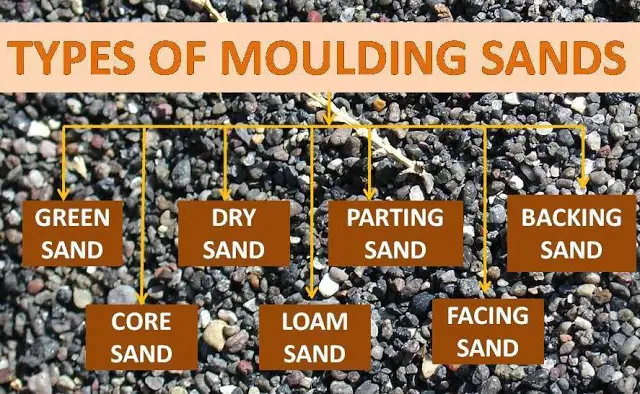

Moulding sand is mainly divided into natural sand and synthetic sand. The various types of moulding sand are. Molding sands can also be classified according to their use into number of varieties which are described below.

Here we are going to discuss about different types of moulding sand. Sometimes a casting is to be made hollow or with cavities in it. Clay sand is the mixture of natural silica sand clay additives and water.

Its principal use is in making molds for metal casting. Types of Molding Sand. Types of Moulding Sand.

Molding sands can also be classified into various types according to their use are backing sand core sand dry sand facing sand green sand loam sand parting sand system sand. In baking owens prepared sand molds are baked at 200-300C degrees of temperatures. The compressive strength is generally 005 to 01 Mpa.

Properties of moulding sand. Types of Moulding Sand. There are many recipes for the proportion of clay but they all strike different balances between moldability surface finish and.

It is basically the mixture of sand clay and water. Oxides of iron magnesia soda potash lime and water are the other substances which are found in the moulding sand. A core is defined as a sand shape which is exactly similar to the cavities.

Backing sand or floor sand. This sand is used during making of the mould to ensure that green sand does not stick to the pattern and the cope and drug parts can be easily separated for removing the pattern without causing any damage to the mould. Each sand has slightly different properties making some sands more suitable for construction projects than others.

The casting of the dry sand is heavy and large. HeyTypes of Moulding SandGreen Sand.

Types Of Sand Used In Moulding Process Mech4study

Different Types Of Molding Sand Used In Casting Process Studentlesson

What Is Molding Sand Types And Properties Engineering Choice

0 Comments